Copyright © Shenzhen Pengyuhua Technology Co., Ltd. All Rights Reserved. Site Map

- +86-13603064867

- pengyuhuavip@163.com

- 101, Building B, No. 16 Xinghua South Road, Pingxi Community, Pingdi Street, Longgang District, Shenzhen City, Guangdong Province

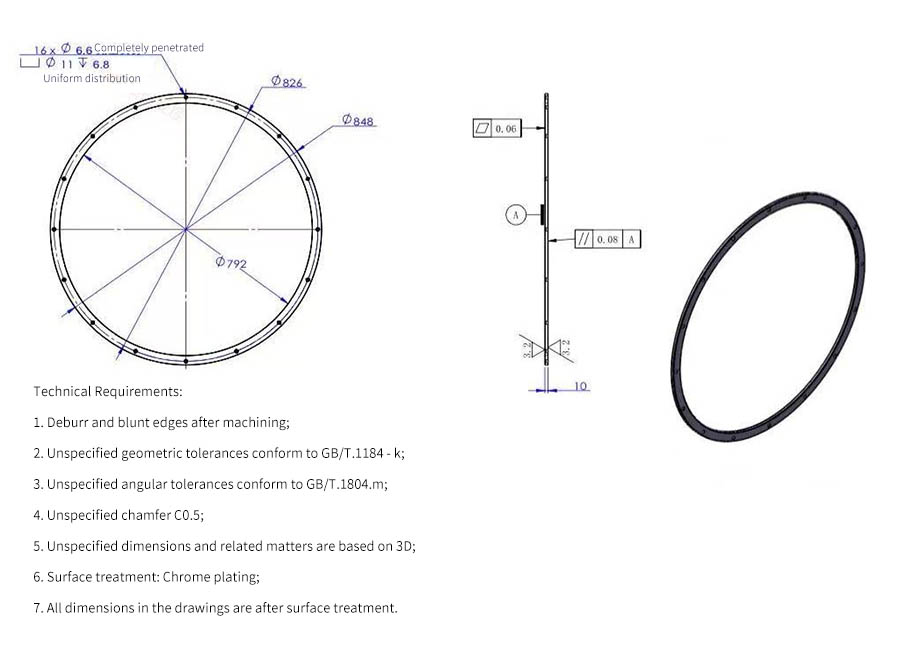

Customer Requirements | Strictly follow the drawings for processing to ensure positional tolerances. |

Processing difficulties | The workpiece is large, hollowed out in the middle, and deformed during processing. |

Solution | Making slider fixtures |

Material Name | No. 45 concentrate |

Cutting dimensions | 848*848*10.3 |

Surface materials | Chrome plating |

Processing flow | 1. CNC machine the inner and outer circles and holes according to the drawing. |

2. Heat treatment to relieve stress and correct alignment | |

3. Fabricate the fixture: base plate 1200*1200*20mm, with 4 R424 sliders on the front, back, left, and right sides. | |

4. Grind the base plate of the tooling on a grinding machine, then install the slide block, and finally place the workpiece on top, using the slide block to hold it in place. | |

5. Grind the material on a grinding machine by rotating it forward and backward three times until it reaches the thickness required by the drawing. | |

6. Three-dimensional detection | |

Test results | Flatness 0.03, parallelism 0.04, acceptable. |

Customer Conclusion | After inspection by our quality control colleagues, the workpiece is found to be qualified according to the drawing requirements. |